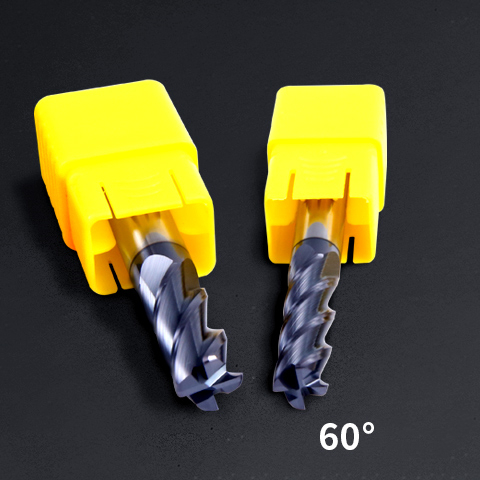

HRC 60 4 Flutes Corner Ukujikeleza End Mill Radius Cutter

IParameter yeMveliso

| Uhlobo | HRC 60 4 Flutes corner rounding end Mill | Izinto eziphathekayo | Intsimbi yeTungsten |

| Isixhobo soMsebenzi | Intsimbi yeCarbon;Intsimbi yengxubevange;Intsimbi yentsimbi;intsimbi engatyiwa;intsimbi eqinileyo | Ulawulo lwamanani | CNC |

| Ipakethe yezoThutho | Ibhokisi | Flute | 4 |

| Ukwaleka | AlTiSiN | Ukuqina | HRC60 |

Uphawu

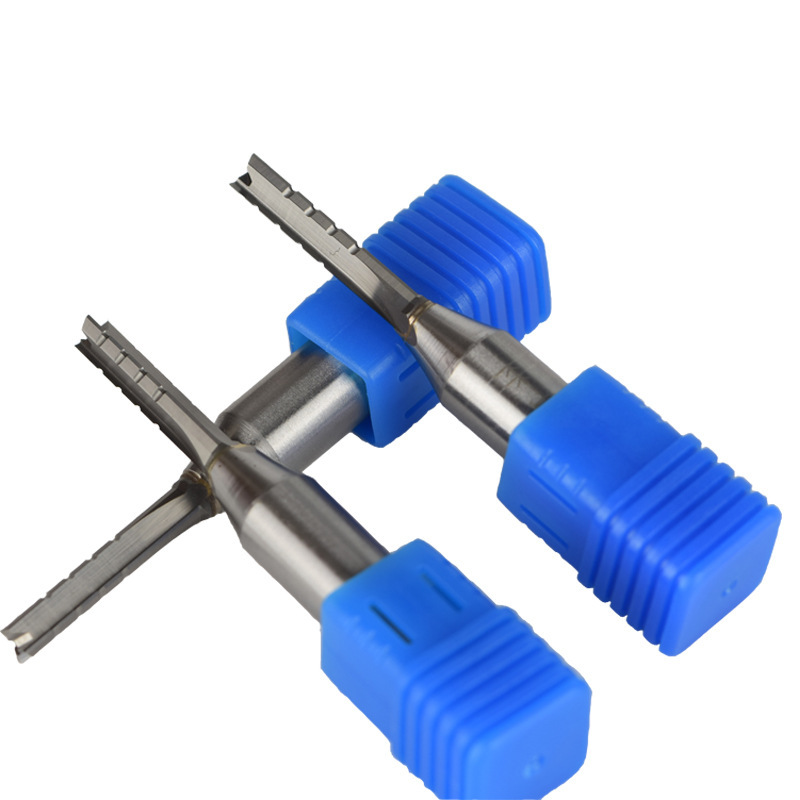

I-1.Sebenzisa i-nano-tech, ubunzima kunye nokuzinza kwe-thermal ukuya kwi-4000HV kunye ne-1200 degree, ngokulandelanayo.

2. Uyilo oluphindwe kabini luphucula ukuqina kunye nokugqiba umphezulu ngokufanelekileyo. Ukusika umgca phezu kweziko kunciphisa ukuchasana kokusika. Umthamo ophezulu we-junk slot unceda ukususwa kwetshiphu kunye nokwandisa ukusebenza kakuhle komatshini.

Imiyalelo yokusetyenziswa

Ukuze ufumane indawo engcono yokusika kunye nokwandisa ubomi besixhobo. Qinisekisa ukusebenzisa ukuchaneka okuphezulu, ukuqina okuphezulu, kunye nezibambi zezixhobo ezilungelelanisiweyo.

1. Ngaphambi kokusebenzisa esi sixhobo, nceda ulinganise ukuphambuka kwesixhobo. Xa ukuchaneka kwesixhobo sokuphambuka kudlula i-0.01mm, nceda ulungise ngaphambi kokusika

2. Ubude obufutshane besixhobo esiphuma kwi-chuck, ngcono. Ukuba isixhobo esiphumayo sinde, nceda unciphise isantya sokulwa, isantya sokutya okanye ukusika inani uwedwa

3. Ukuba ukungcangcazela okungaqhelekanga okanye ingxolo kwenzeka ngexesha lokusika, nceda unciphise isantya se-spindle kunye nesixa sokusika de kube imeko itshintshile.

4. Izinto zensimbi zipholile nge-spray okanye i-jet yomoya njengendlela esebenzayo yokwenza i-titanium ephezulu ye-aluminium ibe nefuthe elihle. Kucetyiswa ukuba kusetyenziswe ulwelo lokusika olungenamanzi kwintsimbi engenasici, i-titanium alloy okanye i-alloy-resistant alloy.

5. Indlela yokusika ichaphazeleka ngumsebenzi, umatshini, kunye nesoftware. Le datha ingentla yeyokukhangela. Emva kokuba imeko yokusika izinzile, ukwandisa izinga lokutya nge-30% -50%.

Sebenzisa

Isetyenziswa kakhulu kwiinkalo ezininzi

Ukwenziwa kweAviation

Ukuveliswa koomatshini

Umenzi wemoto

Ukwenza umngundo

Ukwenziwa koMbane

Ukusetyenzwa kweLathe

Q1: Ndingayifumana isampuli yovavanyo?

A: Ewe, sinokuxhasa isampuli. Isampulu iya kuhlawuliswa ngokufanelekileyo ngokwengxoxo phakathi kwethu.

I-Q2: Ngaba ndingayongeza i-logo yam kwiibhokisi / iibhokisi?

A: Ewe, i-OEM kunye ne-ODM ziyafumaneka kuthi.

Q3: Ziziphi iingenelo zokuba ngumthengisi?

A: Isaphulelo esikhethekileyo Ukhuseleko lweNtengiso.

Q4:Ungawulawula njani umgangatho weemveliso?

A: Ewe, sineenjineli ezilungele ukuncedisa abathengi ngeengxaki zenkxaso yezobuchwepheshe, nayiphi na imiba enokuthi ivele ngexesha lokucaphula okanye ukufakwa kwenkqubo, kunye nenkxaso ye-aftermarket. I-100% yokuzihlola ngaphambi kokupakisha.

I-Q5: Ngaba ndingandwendwela umzi-mveliso wakho ngaphambi komyalelo?

A: Ngokuqinisekileyo, wamkelekile utyelelo lwakho lwefektri.